How Sake is Made: Overview of the Production Process

A fascinating explanation of the sake brewing process from ingredient selection to bottling. Discover the craftsmanship and culture behind Japanese sake.

How Sake is Made: Overview of the Production Process

Sake brewing is not mere manufacturing but “the fusion of art and science.” When polished rice meets koji mold, yeast, and water, a bottle of Japanese sake is born. The more you understand the process, the more special each sip becomes.

Overall Production Process

Here are the typical 9 steps involved in making Japanese sake:

- Rice preparation (washing, soaking, steaming)

- Koji making

- Sake mother cultivation

- Moromi fermentation

- Pressing

- Filtration

- Pasteurization

- Aging

- Blending and bottling

The Main Ingredients

Sake Rice (Sake-Brewing Rice)

Unlike rice eaten daily, “sake rice” has been specially bred for sake brewing. It features larger grains with a white, starchy center called “shinpaku.”

- Yamada-nishiki: The most premium “king of sake rice”

- Gohyakumangoku: Suitable for clean, crisp flavors

- Omachi: Wild and full-bodied character

- Miyama-nishiki: Balanced type suitable for cold regions

Water

Over 80% of sake is water. Whether it’s soft or hard water affects the sake’s character.

- Soft water: Creates smooth, gentle mouthfeel

- Hard water: Produces robust body and richness

Iron and manganese cause off-flavors, so their absence is crucial.

Koji Mold

Koji mold (Aspergillus oryzae) is the tiny “magician” that converts rice starch into sugar. It’s a vital element that influences flavor and aroma.

Yeast

Yeast is the key player that converts sugar into alcohol and aroma compounds. Ginjo aromas and fruit-like fragrances are all produced by yeast.

Deep Dive into the Process

Rice Polishing and Steaming

Polishing removes the outer layers of rice, eliminating sources of off-flavors. Premium sake may be polished down to 60% or less.

Steaming (not boiling) softens the surface while keeping the core firm.

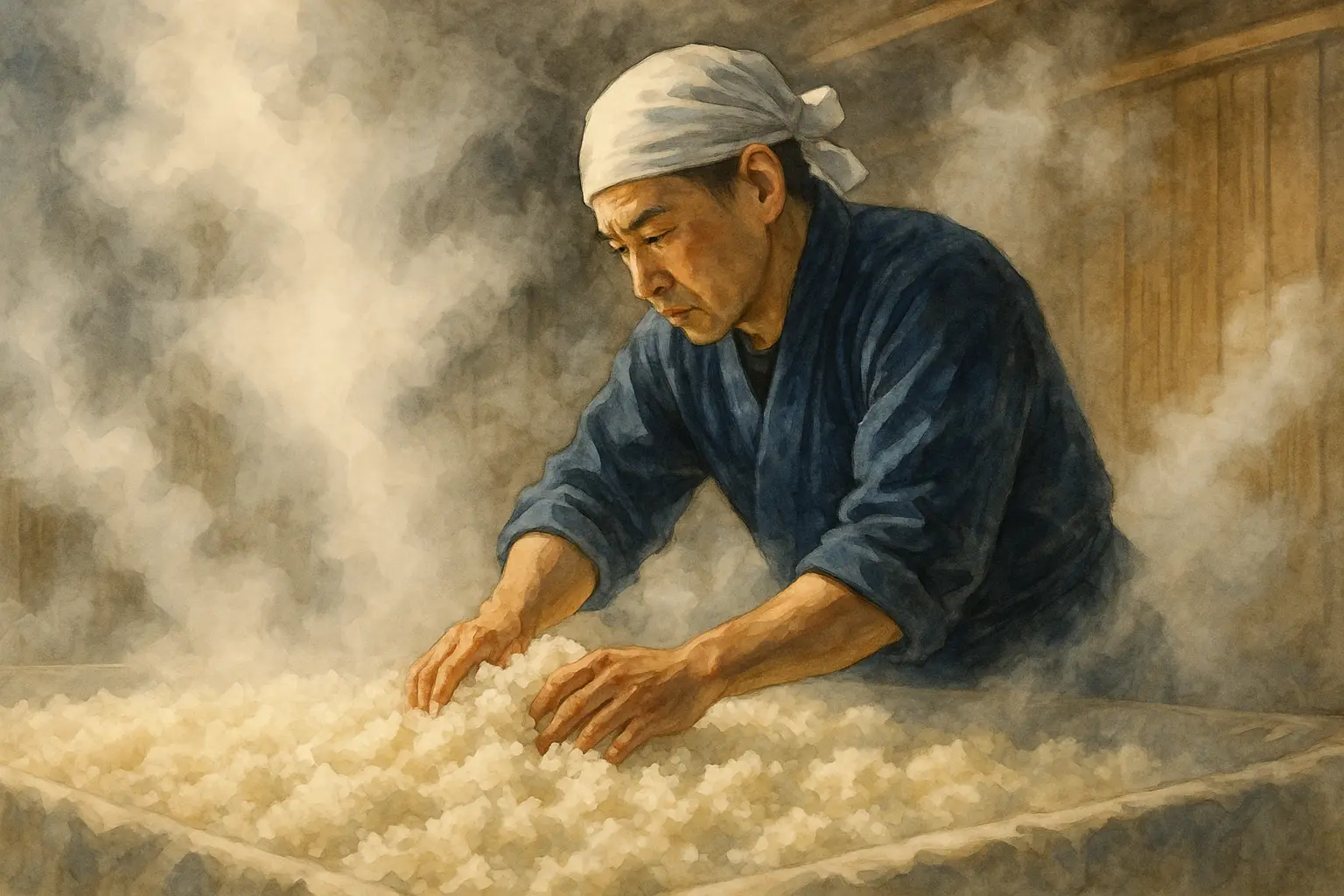

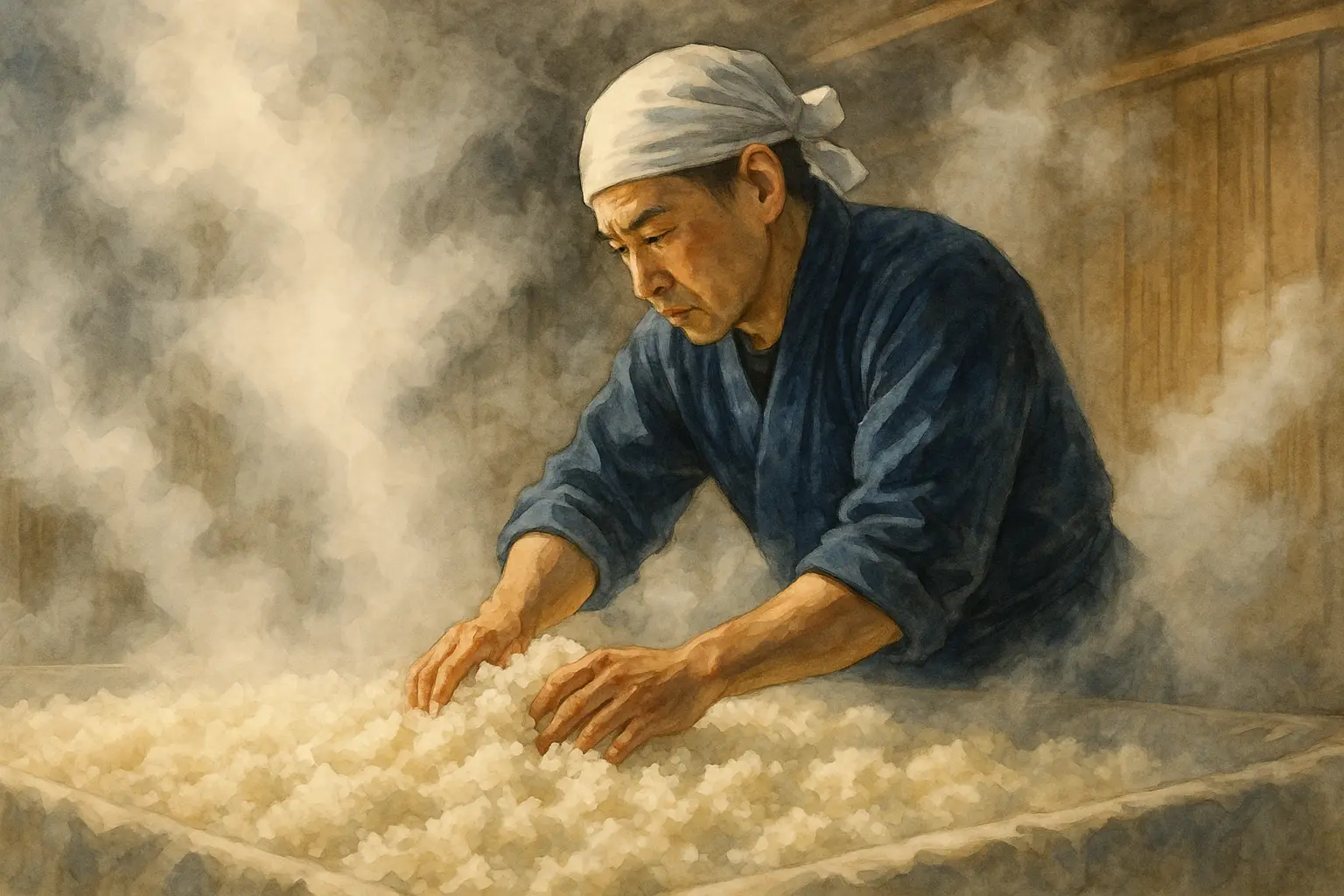

Koji Making (About 48 hours)

- Day 1: Sprinkle koji spores on steamed rice

- Day 2: Carefully control temperature and humidity while cultivating

- Result: White, fluffy koji is completed

The quality of koji determines the quality of sake.

Sake Mother Making (Moto)

A starter culture to cultivate strong yeast. Methods like sokujo, kimoto, and yamahai create different flavors.

- Sokujo-moto: Clean and fruity

- Kimoto/Yamahai-moto: Complex with strong umami

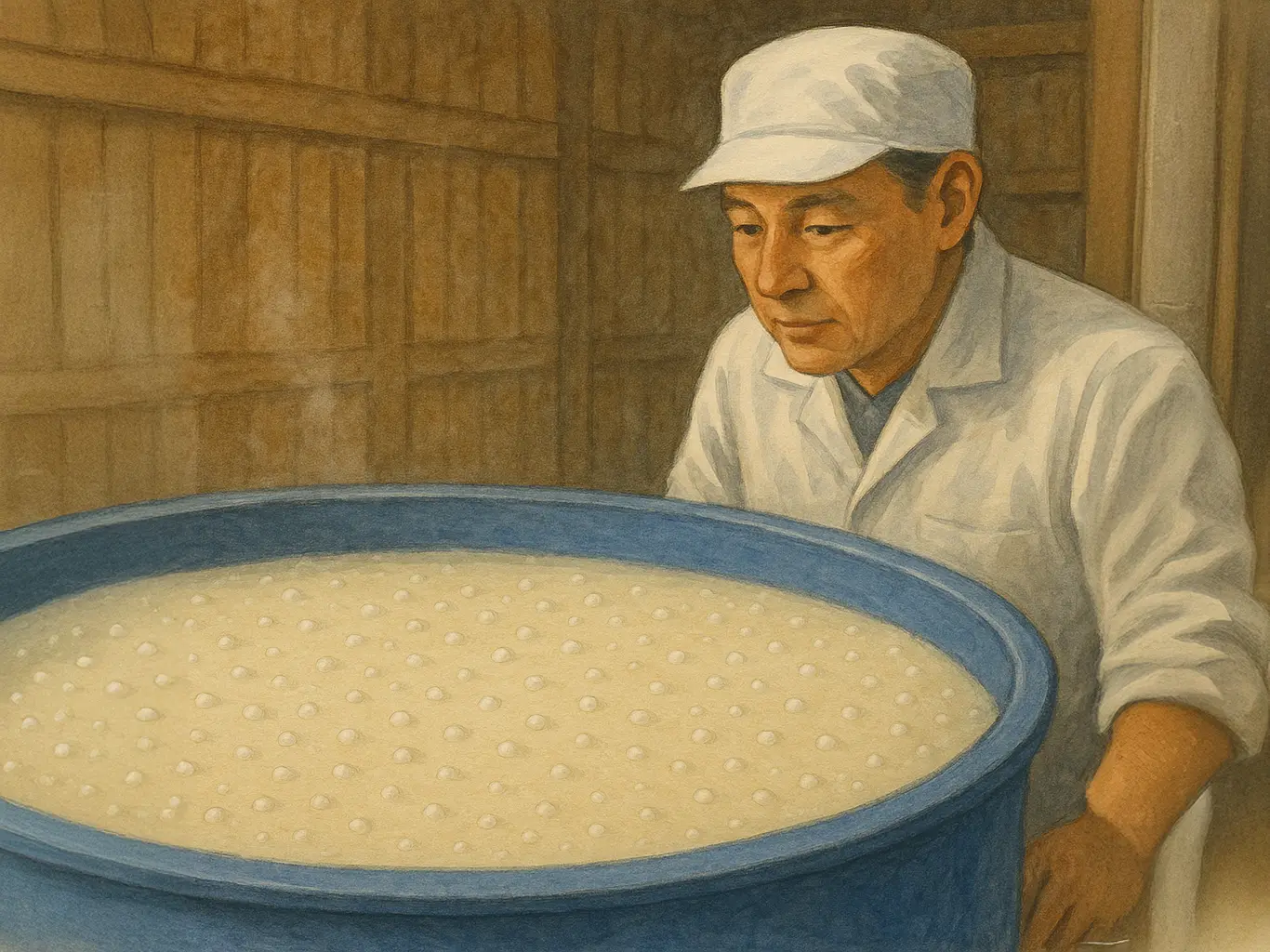

Moromi Fermentation

The characteristic “parallel fermentation” of sake simultaneously proceeds with saccharification and alcohol fermentation.

- Fermentation period: 2-4 weeks

- Temperature control is crucial

- Three-stage brewing (hatsuzoe, nakazoe, tomezoe)

Pressing and Filtration

Separating sake from sake lees using “fune pressing” (slow pressing in bags) or mechanical “accordion press.”

The first portion “arabashiri” is light and fresh. Middle and final portions have different flavor profiles.

Pasteurization and Aging

Heating to 60-65°C deactivates enzymes and microorganisms. This “hi-ire” process is typically done twice for most sake.

Aging mellows and integrates the sake’s flavors.

Regional Diversity and Styles

- Niigata: Light and dry, soft water brewing

- Nada (Kobe): Full-bodied, hard water usage

- Fushimi (Kyoto): Elegant and rounded

- Hokkaido: Clear finish characteristic of cold regions

Summary: Every Drop Contains Craftsman’s Dedication

Japanese sake is not just an alcoholic beverage. A single grain of rice, through countless steps and time, transforms into the “culture” that is Japanese sake.

Next time you drink sake, please imagine the story behind the label.